UP550 डेटा पत्रक PDF( Datasheet डाउनलोड )

डेटा पत्रक - Program Controller - Yokogawa

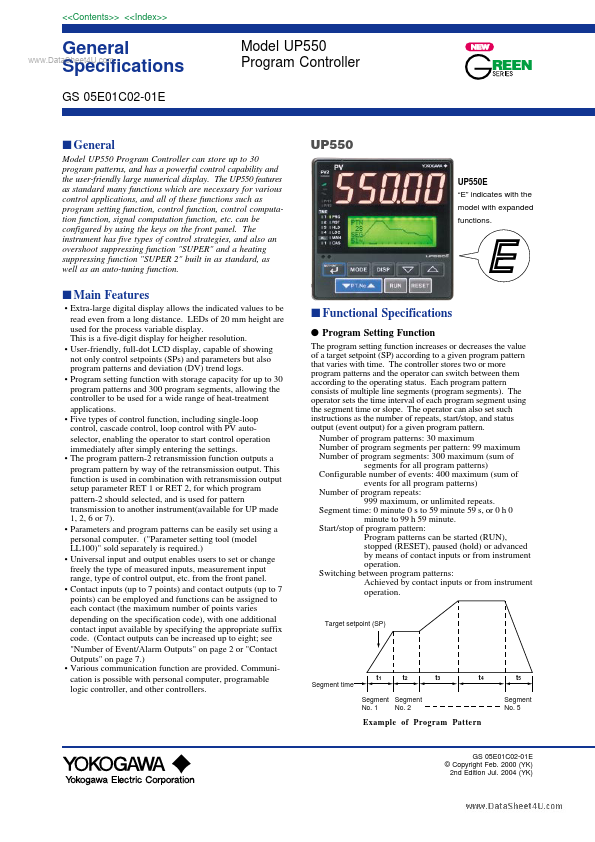

| भाग संख्या | UP550 | |

| समारोह | Program Controller | |

| मैन्युफैक्चरर्स | Yokogawa | |

| लोगो |  |

|

| पूर्व दर्शन | ||

| डाउनलोड | [ UP550 Datasheet.PDF ] | |

शेयर लिंक

अनुशंसा डेटापत्रक

| भाग संख्या | विवरण | विनिर्माण |

| UP550 | Program Controller | Yokogawa |

| UP550 | Program Controller User Manual | Yokogawa |

www.DataSheet.in | 2017 | संपर्क | खोज | English |